Optimizing IPS with artificial and human intelligence

AI has become a hot topic across every industry since the birth of ChatGPT. While some may worry that the potential of AI is overhyped, the impact it can have on integrated product support (IPS) for aerospace and defense cannot be ignored. For example, for organizations that build and maintain A&D assets, embedding AI and data analytics into interactive electronic technical publications (IETPs) transforms IETPs into dynamic resources that provide real-time insights and predictive analytics, enhancing decision-making and efficiency.

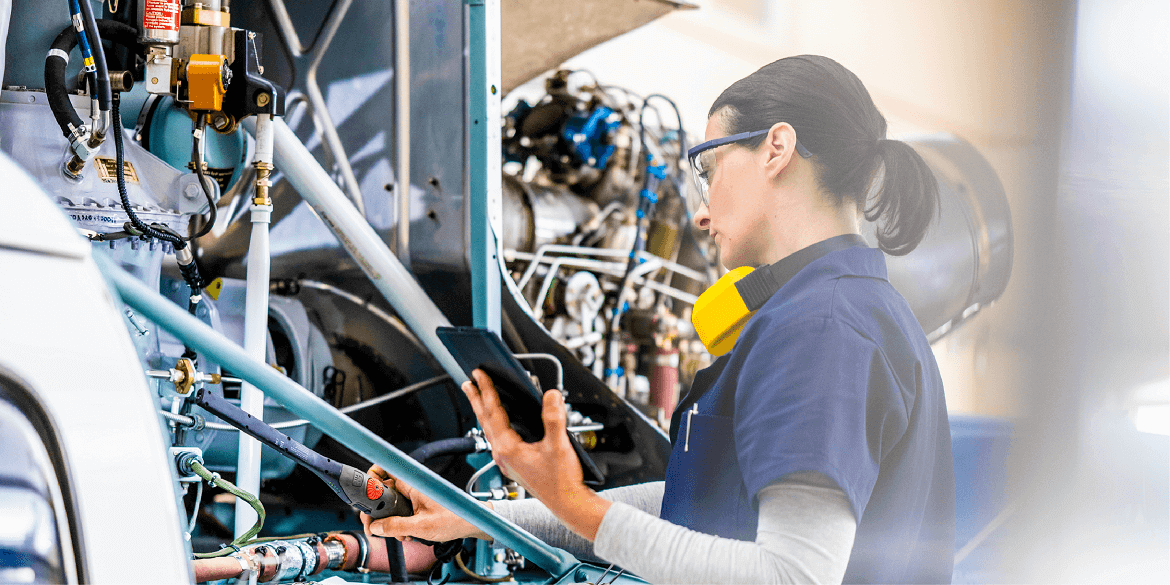

The true power of AI is unlocked when paired with the right technological infrastructure and the invaluable human expertise that drives innovation. Technologies like IoT and edge computing are essential in harnessing AI’s capabilities, ensuring real-time data processing and enhancing decision-making processes. However, it’s the human element – the skilled maintainers on the ground – that remains the cornerstone of effective IPS. By leveraging your maintainers’ insights and experiences, you can create a synergy between artificial and human intelligence that leads to unprecedented efficiency and reliability in maintenance operations.

Why you need to be integrating AI and data analytics into your IETPs

The integration of artificial intelligence (AI) and data analytics into IETPs optimizes predictive maintenance, which not only improves operational efficiency but also minimizes costs associated with unplanned repairs and part replacements.

AI-driven insights significantly enhance decision-making processes by analyzing vast amounts of data quickly and accurately. Maintenance managers can predict potential equipment failures before they occur, allowing for proactive interventions that reduce downtime and extend the lifespan of critical assets.

The potential for more advanced machine learning models within IETPs is immense. As AI technology continues to evolve, these models will become even more adept at identifying patterns and anomalies, further optimizing efficiency and accuracy in maintenance operations. The continuous learning ability of AI ensures that IETPs remain at the forefront of innovation, adapting to new data and providing increasingly precise recommendations.

The importance of IoT and edge computing for real-time data processing

The internet of things (IoT) is the network of interconnected devices that collect and exchange data, while edge computing brings processing capabilities closer to where the data is generated. Together, they enable rapid data analysis without the latency associated with other solutions.

Incorporating IoT data and edge computing into IETPs allows for real-time data processing, ensuring that technical publications are always up to date with the latest information. This capability is crucial for maintenance professionals who rely on accurate data to make informed decisions quickly. Real-time updates help in promptly identifying issues, thus allowing for immediate corrective actions, which minimize downtime and improve overall operational efficiency.

Looking ahead, the expansion of IoT devices in maintenance environments promises to create even more responsive systems. As more sensors and smart devices are integrated into the maintenance process, the ability to monitor assets and predict issues will become increasingly sophisticated. This evolution will enable maintenance teams to transition from reactive to proactive strategies, further enhancing the reliability and availability of critical aerospace and defense systems.

Capturing the voice of the maintainer with closed-loop feedback systems

Implementing closed-loop feedback systems in IETPs helps capture user comments and transactional data, which can be used for reliability analysis and continuous improvement.

These systems operate by continuously capturing and analyzing data from various maintenance activities, enabling a streamlined feedback loop that directly informs ongoing improvements. By integrating real-time feedback into maintenance processes, IETPs ensure that technical documentation remains accurate, relevant and effective, providing maintenance teams with the essential insights needed for optimal performance.

Leveraging captured data enhances the reliability and accuracy of maintenance procedures. The continuous feedback loop allows for iterative improvements, ensuring that any discrepancies or inefficiencies are promptly addressed. This results in more precise maintenance operations, reduced downtime and increased operational efficiency.

The future of closed-loop feedback systems in IETPs promises even greater advancements. The integration of more comprehensive data sets will enable a holistic approach to system improvements. By incorporating data from a broader range of sources, these systems will provide a more complete picture of maintenance needs and challenges. Integrated AI capabilities can help the maintenance manager interpret the data and can offer suggestions, facilitating more informed and effective decision-making.

Having AI recommendations in the procedural flow for technicians also necessitates a feedback mechanism to correct the automated system when it gets things wrong. A known issue in deploying AI-based abilities is that the AI sometimes produces incorrect suggestions, or ‘hallucinations’.

With the integration of AI and data analytics into IETPs, A&D maintenance professionals can revolutionize their integrated product support. The most effective systems will be built on a solid technology foundation through the use of IoT and edge computing for swift data processing, and will implement closed-loop feedback systems to gather data from the industry’s most valuable resource – the maintainers themselves. By leveraging AI-driven insights and real-time data processing, organizations can optimize predictive maintenance, reduce downtime and minimize costs associated with unexpected repairs. However, this value can only be fully realized when combined with the maintainer overseeing the direction.